AGRIOIL – S.P.A.

BIOLIVAGOLD PROJECT – F/200126/01/X45

Valorization of olive mill by-products through the extraction of biomolecules for nutraceutical, agronomic, and feed applications.

Axis 1 Investment Priority 1.b Action 1.1.3 LDR

For a long time, vegetation water has been considered one of the most potentially polluting agents among agro-industrial effluents. The BIOLIVAGOLD project involves recovering high-value organic components for use in the cosmetic, food, and pharmaceutical industries; thus, vegetation water is no longer a cost but a resource.

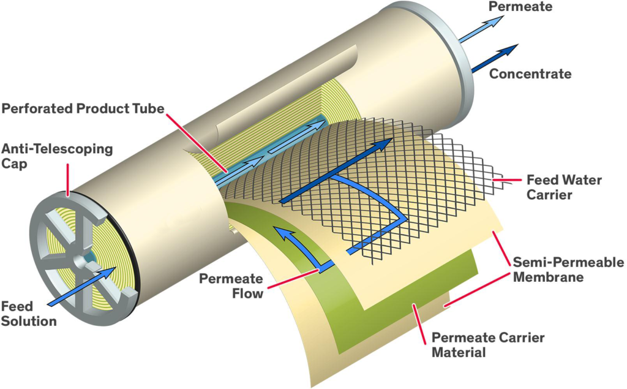

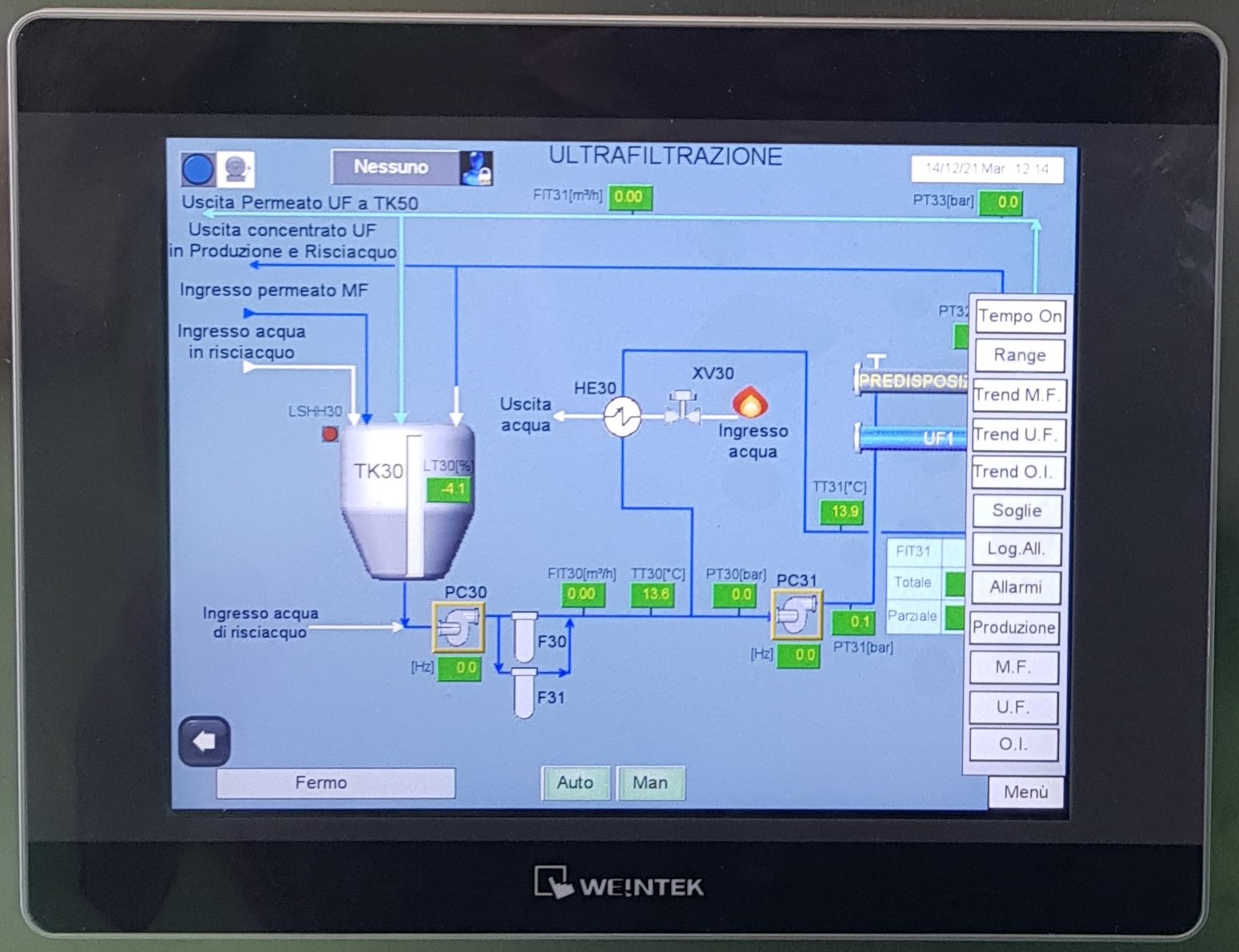

Over the 48 months of the project, through industrial research, the most innovative technologies in the field of membrane physical separation were studied. Subsequently, with experimental development, a pilot plant was constructed, serving as a preparatory step for the subsequent industrial-scale design of a polyphenolic extraction plant to solve the issue of olive mill vegetation water.

Additionally, there is economic optimization by comparing an industrial plant with smaller ones located in a specific olive production area.

GENERAL CONTRACT S.R.L. – OBJECTIVE 1

Engineering the process of separating biochemical components from olive mill vegetation water.

AGRIOIL S.P.A. – OBJECTIVE 2

Implementing the system for separating biochemical components from olive mill vegetation water.

GENERAL CONTRACT S.R.L. – OBJECTIVE 3

Characterizing by-products to extract bioactive and non-bioactive compounds, testing matrices for nutraceutical, agronomic, and feed applications.

GENERAL CONTRACT S.R.L. – OBJECTIVE 4

Industrial characterization.