Sustainability at 360°

The BIOLIVAGOLD project, promoted by AGRIOIL SPA, fits into the context of agri-food sustainability, a growingly important theme for its environmental, social, and economic implications. Sustainability is essential for the development of a resilient, responsible, and circular economy, and innovation plays a strategic role in achieving these goals. One crucial aspect is combating food waste, which requires practical and concrete initiatives to be effective.

Olive Biomass

In the olive-oil production chain, olives and oil represent only a small part of the biomass produced. The olive’s weight is equivalent to pruning residues, while the oil constitutes about 20% of the olive’s weight. The remaining biomass is considered processing residue, which can be reused as a by-product or otherwise defined as waste. Olive pruning residues are a significant resource, averaging 10-30 kg of plant material removed annually per mature plant. Some of these residues are used within the company, while the rest is disposed of through agronomic practices, such as burial, which can generate side effects like pest development.

Vegetation Water (VW)

Vegetation water (VW) is the main by-product of the oil extraction process. These waters, which represent 97% of the total polyphenols present in the olive, can vary in quantity and composition depending on the extraction method used. In new water-saving centrifugal plants, VW approaches 33% of the mass of the olives processed. Although not toxic, VW is highly polluting due to the high load of organic substances and the large volumes produced in a short time.

The BIOLIVAGOLD Project

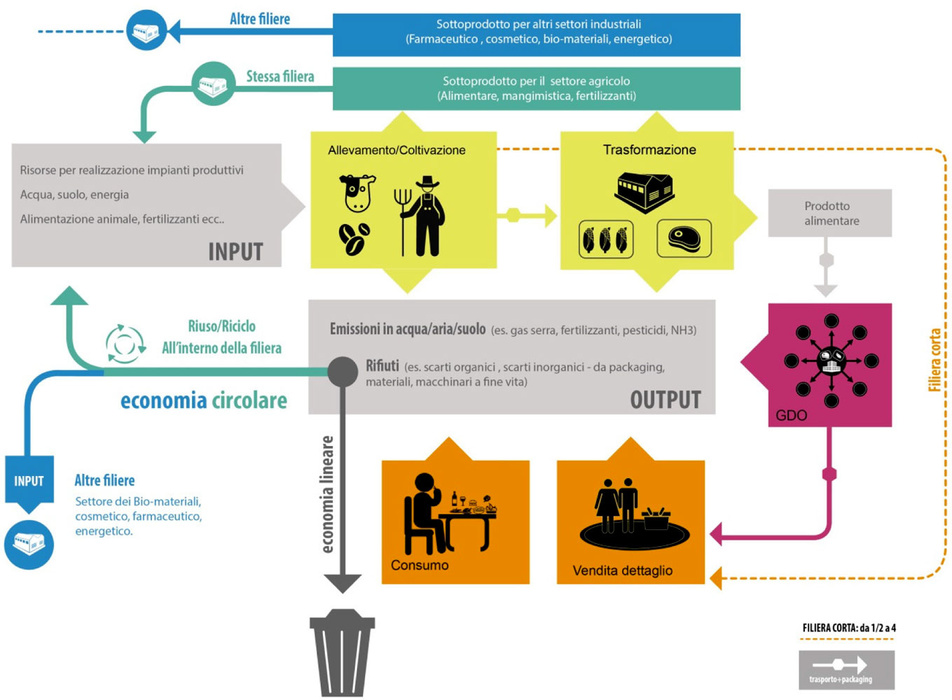

The BIOLIVAGOLD project has been admitted to the incentives of the National Operational Program of MiSE “Enterprises and Competitiveness” 2014-2020 ERDF, in line with the National Smart Specialization Strategy in the sectors “Intelligent Factory” and “Agrifood”. The goal is to find economically advantageous and environmentally compatible solutions to transform production waste into new raw materials, promoting sustainable development and a circular economy.

ENEA has developed a process based on tangential membrane filtration to treat VW, fractionating and recovering suspended organic matter, a polyphenolic concentrate, and purified water. The organic matter depleted of polyphenols can be used to produce biogas or compost, while the polyphenols can be used in the food, pharmaceutical, and cosmetic industries. The recovered water can be used as a base for new beverages.

Collaborations and Future Goals

The VW separation process is optimized at the Agro-Industrial Process Technology Hall of the Bioproducts and Bioprocesses Laboratory at the Casaccia Research Center, in collaboration with Agrioil and General Contract Srl. The partnership aims to develop a line of products for the food and cosmetic market and create treatment systems replicable in other industrial contexts.

The BIOLIVAGOLD project represents a significant step towards 360° sustainability, transforming olive production waste into valuable resources and contributing to a more circular and sustainable economy.

For more details, you can download the complete BIOLIVAGOLD project PDF: